Expert Lift Maintenance Repair Services to Ensure Safety And Security

Wiki Article

Opening the Keys to Effective Lift Services: Professional Insights Revealed

In the world of lift repair work and maintenance, discovering the techniques that lead to efficient and efficient service is akin to deciphering a complex challenge. As we get started on this trip to debunk the secrets behind structured lift repair work, a globe of possibilities arises, assuring a future where downtime is minimized, safety is focused on, and functional excellence comes to be the standard.Usual Lift Repair Challenges

Another widespread difficulty in lift repair work is the absence of correct maintenance records. Without accurate maintenance records, repair work specialists may struggle to detect concerns properly or expect possible troubles. This can result in longer fixing times and enhanced expenses as specialists work to repair problems without historic data to direct them.

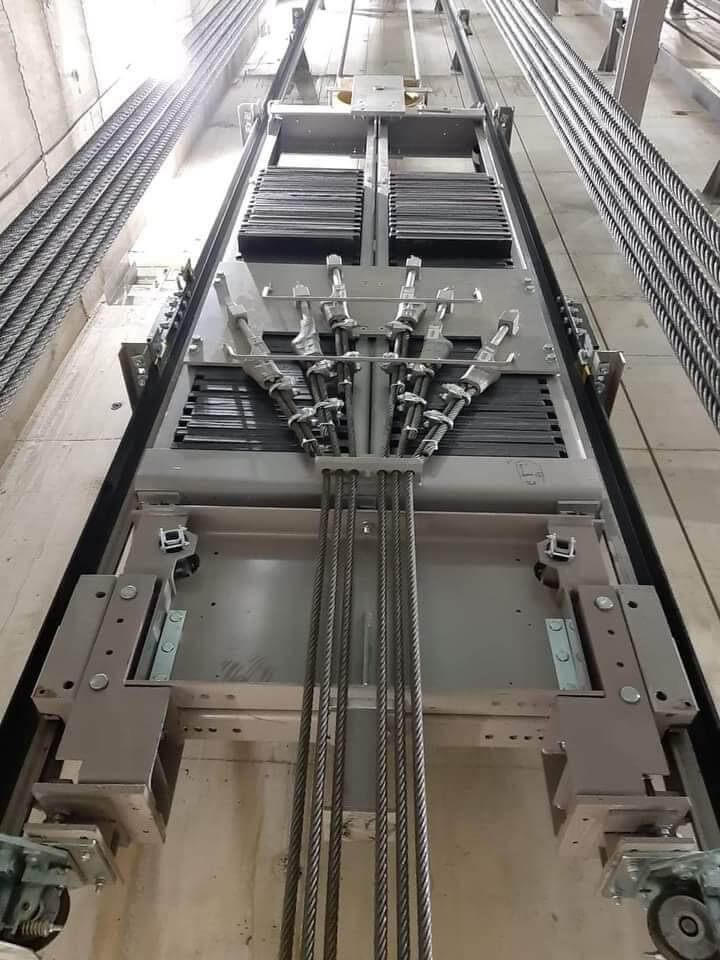

Moreover, availability issues within lift shafts can pose considerable difficulties throughout repairs. Restricted room, awkward angles, and complex machinery can make it challenging for service technicians to reach the required parts for repair, prolonging the total repair work process - Lift Maintenance Repair. By dealing with these typical challenges proactively, lift repair work specialists can enhance operational efficiency and make sure the smooth functioning of vertical transportation systems

Proactive Maintenance Approaches

Implementing proactive upkeep strategies is paramount for ensuring the longevity and ideal efficiency of lift systems. By adopting a proactive strategy to upkeep, structure managers and lift maintenance groups can resolve possible problems before they escalate into expensive repair services or downtime. One efficient technique is to establish a routine maintenance routine that includes complete examinations, lubrication of moving parts, and screening of safety functions.

Furthermore, buying training programs for upkeep personnel can boost their abilities in recognizing prospective concerns and doing preventative maintenance jobs properly - Lift Maintenance Repair. By encouraging upkeep groups with the expertise and tools required to proactively keep lift systems, building proprietors can decrease disturbances, expand the lifespan of their lifts, and guarantee a trusted and risk-free upright transportation experience for owners

Troubleshooting Methods

Reliable fixing strategies are important for immediately recognizing and dealing with issues with lift systems to reduce downtime and guarantee ideal efficiency. One effective strategy is to start with an extensive visual inspection of the lift components, inspecting for any noticeable indications of imbalance, wear, or damages.

Enhancing Fixing Skills

Enhancing proficiency in lift system fixings is a basic element of making certain optimum capability important source and minimizing functional disruptions. Elevator technicians need to continually function on honing their repair skills to fulfill the needs of modern lift systems.Additionally, remaining upgraded with the most recent innovations in lift innovation is important for professionals aiming to boost their fixing abilities. This includes actively looking for details regarding new elements, software application updates, and maintenance techniques to effectively detect and rectify problems. By spending effort and time into continuous understanding and practical experience, elevator specialists can substantially improve their repair service competencies and contribute to the effective performance of lift systems.

Elevating Maintenance Requirements

Boosting maintenance criteria in lift systems is vital for making certain extended functional effectiveness and security. Normal upkeep not only enhances the performance of lift systems but additionally reduces the risk of unforeseen malfunctions and guarantees the safety and security of customers. By adhering to strict upkeep procedures, lift owners and drivers can dramatically reduce the likelihood of pricey repair services and downtime.Applying a comprehensive maintenance schedule that includes normal examinations, lubrication of moving components, and proactive substitute of worn components is vital. Making use of innovative innovations like IoT sensing units and anticipating upkeep software can assist in checking the lift's condition in real-time, allowing timely treatments prior to concerns escalate. Furthermore, providing continual training for maintenance staff on the most recent market requirements and best methods is essential for supporting maintenance quality.

In addition, promoting a society of responsibility and interest to information amongst maintenance teams can further elevate upkeep criteria. Encouraging open interaction channels for attending to and reporting maintenance worries immediately can aid company website in maintaining a high degree of lift system integrity. Ultimately, by boosting and focusing on upkeep criteria, lift systems can run effectively and securely for a prolonged period.

Verdict

Finally, reliable lift repair services require proactive maintenance approaches, repairing techniques, and boosted fixing abilities. By boosting and resolving typical difficulties upkeep standards, upkeep specialists can effectively ensure the smooth procedure of lifts - Lift Maintenance Repair. Applying these professional understandings can lead to boosted efficiency, minimized downtime, and raised safety and check over here security for both travelers and equipmentIn the realm of lift fixing and upkeep, revealing the methods that lead to effective and effective service is akin to understanding a complex challenge.An additional widespread obstacle in lift repair services is the lack of correct maintenance documents. By taking on an aggressive approach to maintenance, structure supervisors and lift maintenance groups can resolve possible problems prior to they escalate right into expensive repairs or downtime.In conclusion, effective lift repair work require aggressive maintenance approaches, troubleshooting techniques, and boosted repair work abilities. By elevating and dealing with typical difficulties maintenance requirements, maintenance specialists can successfully ensure the smooth procedure of lifts.

Report this wiki page